PRECISION MACHINING, INC.

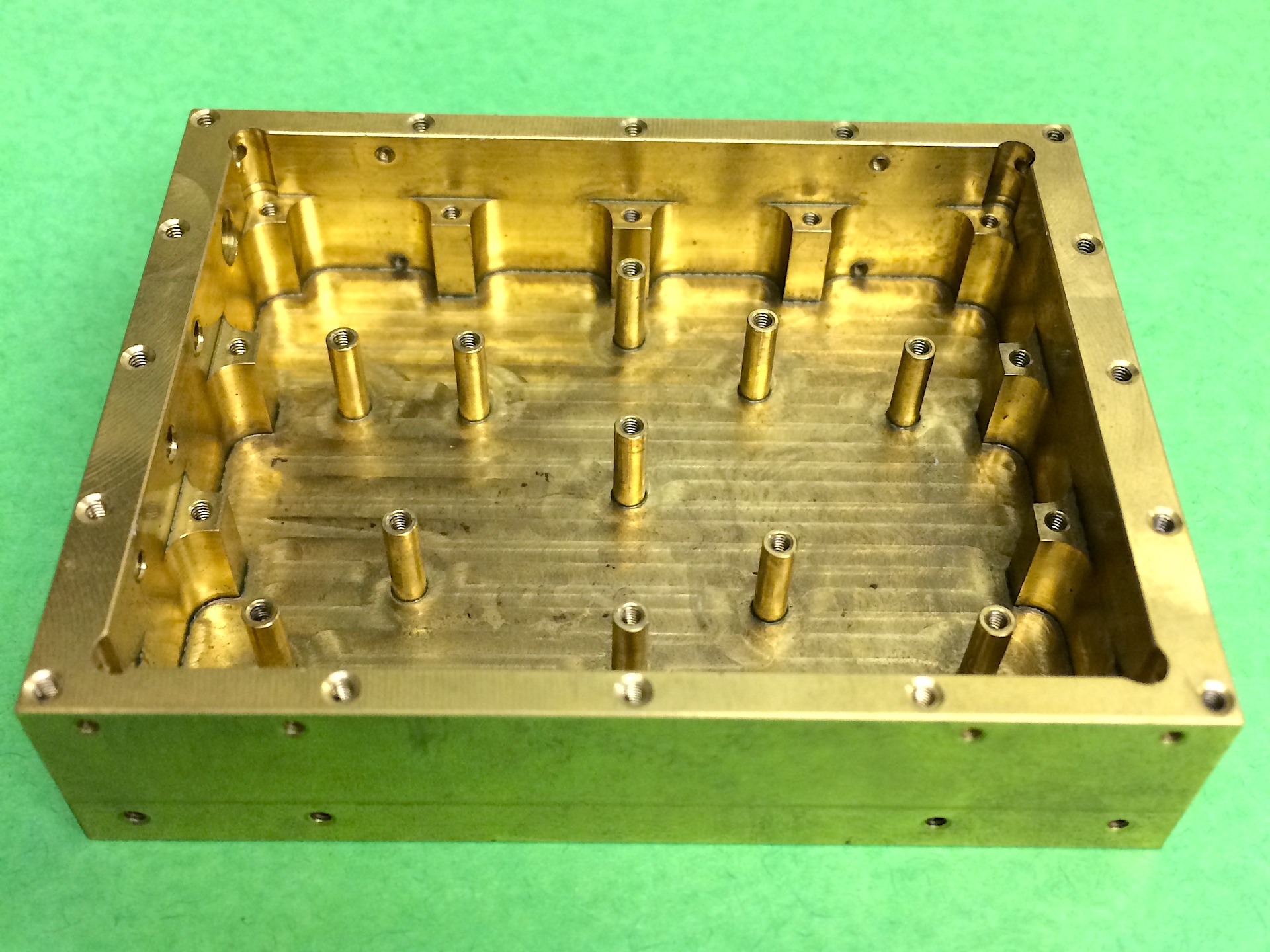

Brass Electronics Box

×

![]()

This piece will be finished with nickel plating, requiring special attention to tolerance to ensure proper clearances in the final assembly after build-up of the plating.

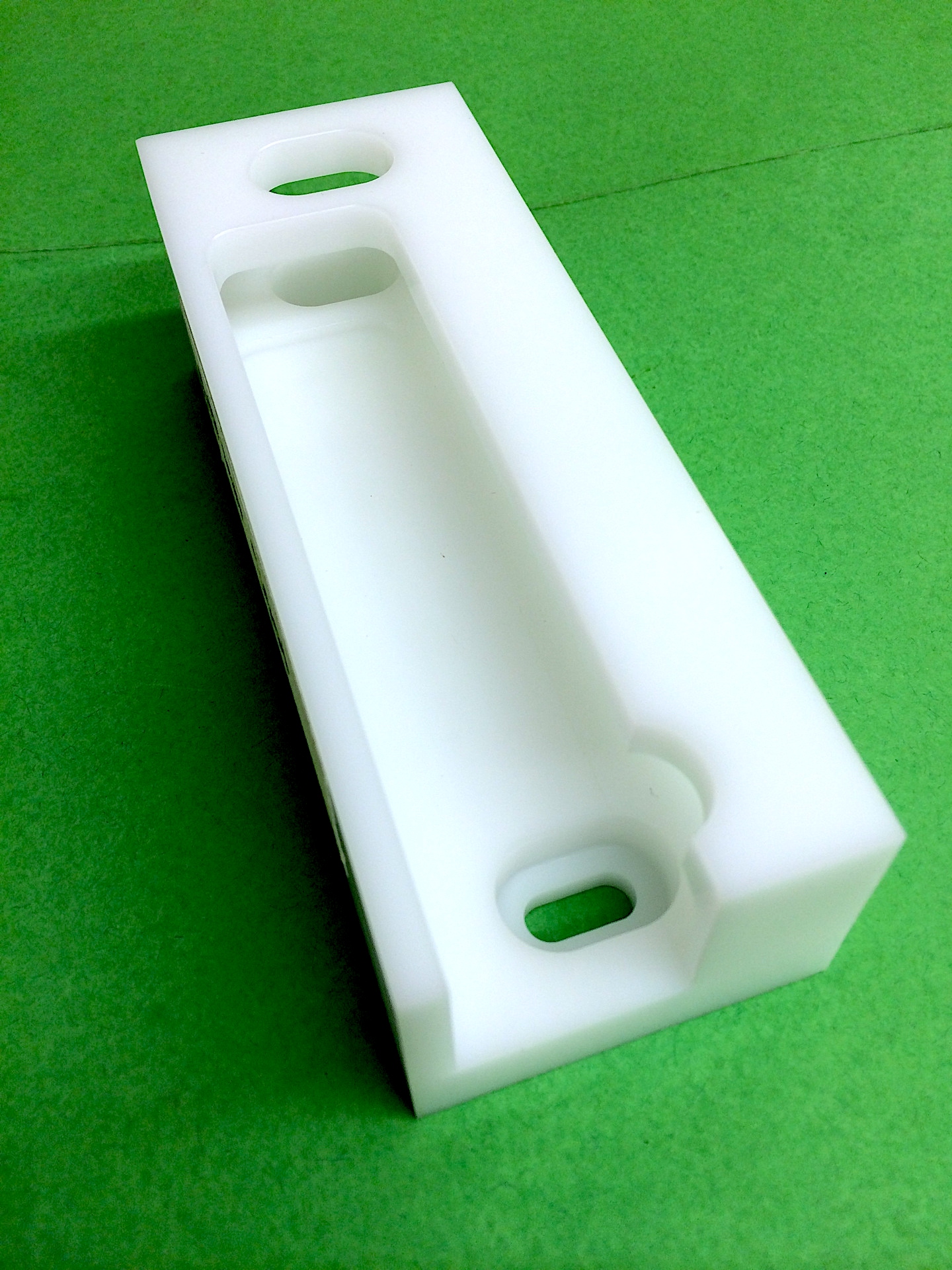

Graphite Shoulder Implant Prototype

×

![]()

Our CNC programmers understand and implement the most optimal toolpaths to create beautiful 3D contours and uphold the engineered functionality.

Acetal Chassis

×

![]()

Our techniques in relaxing material and properly sequencing operations ensure that tolerance and functionality are maintained in the finished part.

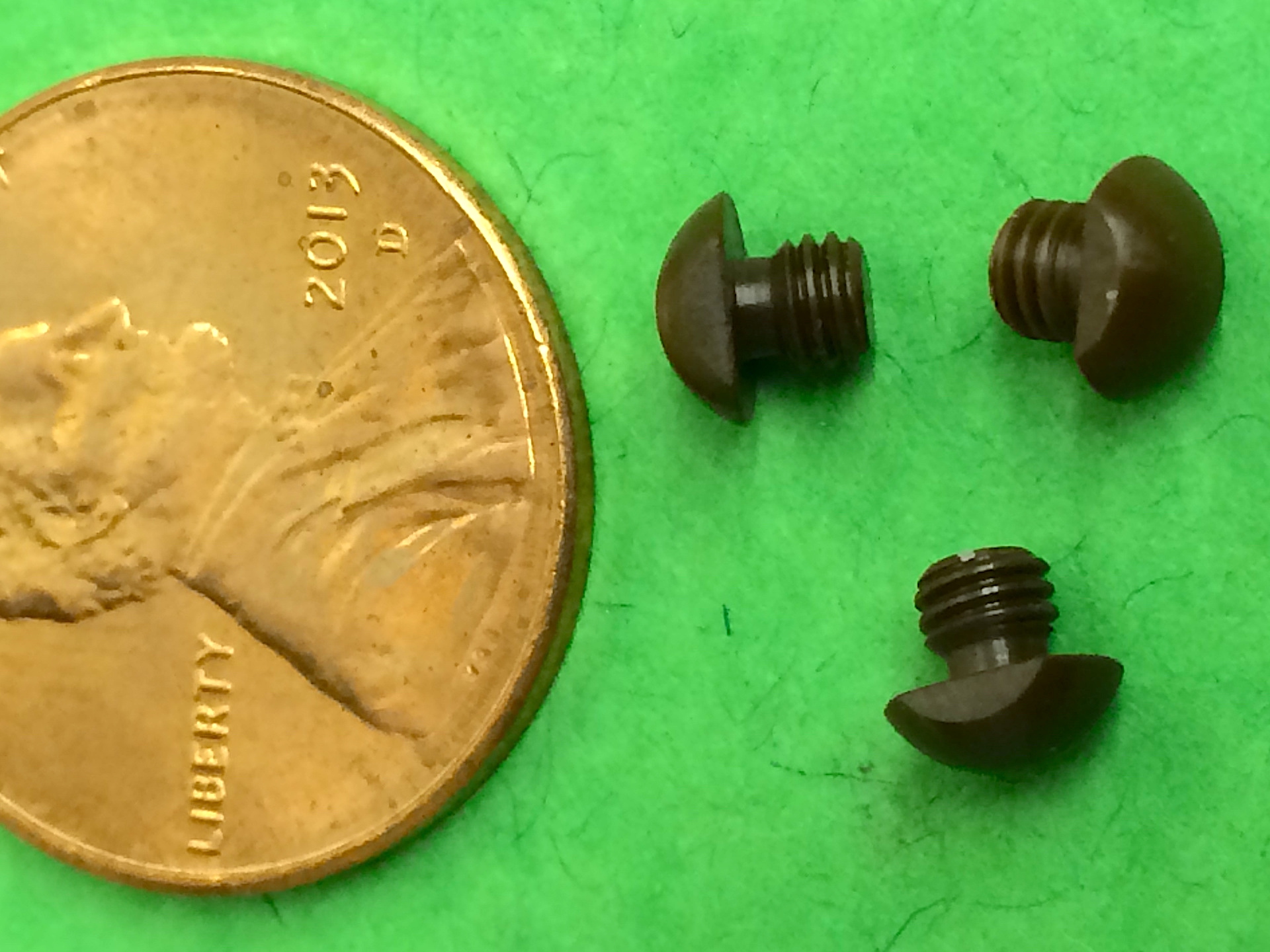

Mini Screws

×

![]()

Our staff is revered for their meticulous attention to detail and vast experience with methods befitting delicate parts.